DISTILLING SOTOL

Harvesting sotol is hard hot work. The jimador uses a sharp blade at the end of a long handle to cut off the plant at its base, then trims off the spines, leaving the heart, called a piña because it looks like a pineapple.

In rough country, the piñas are brought in by burro or mule.

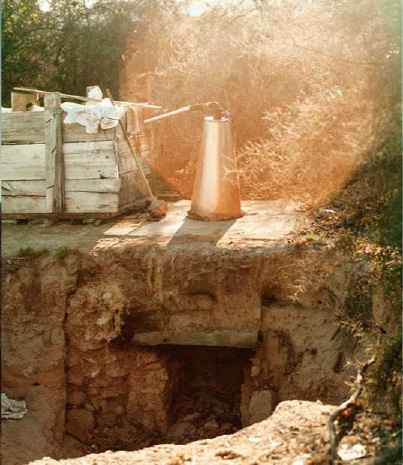

The horno, the oven for artisan roasting the piñas, is traditionally a rock-lined pit oven (some use above-ground ovens). You build a fire in the bottom of the pit, cover the fire with rocks, put the piñas on top of the rocks, cover the piñas with bagasso (the fibrous residue of earlier distillation), then cover it all with earth/sand and let the piñas bake for 3 days, converting carbohydrates in the sotol to fermentable sugars. Commoditized sotols are steamed, like agaves for tequila.

You then cut the roasted pinas into smaller pieces for crushing/milling. These are about to be fed into a mechanical shredder.

Next you put the fibers and liquid from the milled sotol into a wood vat for fermentation. Native wild yeasts convert almost all of the sugars into alcohol, which takes several days, up to two weeks.

Here’s a copper sotol potsill shot by Imbibe. magazine The distillation, using both fibers and liquid, is double, and the stills are pretty small. A couple of days leter you have maybe 60 liters; then you start distilling the next batch.

Freshly distilled. It’s amazing that the stuff straight from the still is a good as or to our taste better than many highly respected spirits, whiskey/cognac/rum/ after years of aging in good oak.