Video Category: Germain-Robin

Tech Note: Gradual Addition of Water to Brandy by Dilution

Tech Note: Descending 9 Year Old Apple Brandy to Bottling Proof by Adding Rainwater

Tech Note: Making Distilling Wine at a High Tech Facility

Tech Note: Freshly Distilled Brandy from Apples

Individual Product: Germain-Robin Single Barrel V320 Riesling

Distillery Post: 2nd half of the Distillation Season

–

We have begun to distill Pinot Noir and other red varietals at the distillery this week. Pinot Noir is our favorite grape to distill and makes up a large portion of the Select Barrel XO.

Final distillation of Pinot Noir from Roederer Estate of Anderson Valley. They used a particular yeast strain called Melody in this batch of wine to give it a more robust and complex profile.

The copper bucket below is set up for catching any distillate in transitioning between cuts as we transfer the condenser’s output from one holding tank to another. At the distillery these tanks are affectionately known as the “hotdog” and “coffin”. Above, samples directly off the still await. Joe will determine when to make the cuts on sense of smell.

The beginning of 2015 distillate “Blend B” that we offer for sale to wineries for their ports. This one is Dolcetto from John Mattern’s Split Rock Ranch in Talmage near the City of Ten Thousand Buddahs and Viognier from Rivino between Ukiah and Hopland along the Russian River.

Notes from Ansley: Early Germain-Robin Part 3 Installing the Still

*

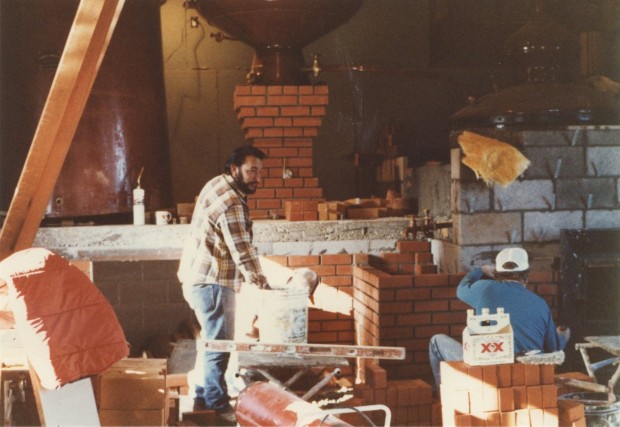

We worked with local masons Fred Rouse and Dave Butler. They didn’t believe us when we told them that this was the only such still in the USA.

We had a scale drawing made by Prulho, in centimeters. There was a lot of jawboning.

Here it is in place before they put the bricks around the pot. We insulated the pot with earth, sand, and diatomaceous earth, the way they used to. This means there is retained heat, which is beneficial around the pot. The same heat dissipates with modern cognac-still insulation.

Dave and Fred laying the brick facing. Behind Dave is the brick pillar they built to hold the preheater. Elegant work.

Fred Rouse’s crew. They enjoyed the job.

Turkish workman Ansley checking it out. Note the rebar for finishing the chimney behind the pot and the leftover firebrick under the condenser platform.

Our lovely old, antique still. It makes very good brandy. We moved the operation in 1998, but we still use it once in a while.

Distillery Posts: Preparing Pear Maceration for the Pear de Pear Liqueur

*

Today we prepared some beautiful Bosc pears for maceration in pear distillate. The infusion will be added to pear brandy distilled from Bartletts to make our Pear de Pear liqueur.

The pears come from the Filigreen orchard in Anderson Valley, where we also source some heirloom apples. They are small, thus intensely flavored, and will improve our pear brandy with “clean and yummy” (Joe Corley) flavors and aromatics. These Boscs are ripe and very sweet therefore it’s great to be able to add an appealing fruity sweetness to the brandy without resorting to sugar.

Bosc Pears

Milling the pears Jeff Desjardins

Jeff Desjardins

Greg Peacock

Notes from Ansley: Early Germain-Robin Part 2

The Still Arrives

Hubert found a beautiful still, wood-fired when assembled in the 1930s, in an abandoned distillery near Cognac. He had it refitted at Prulho, who added two coils to the condenser and shipped it to California.

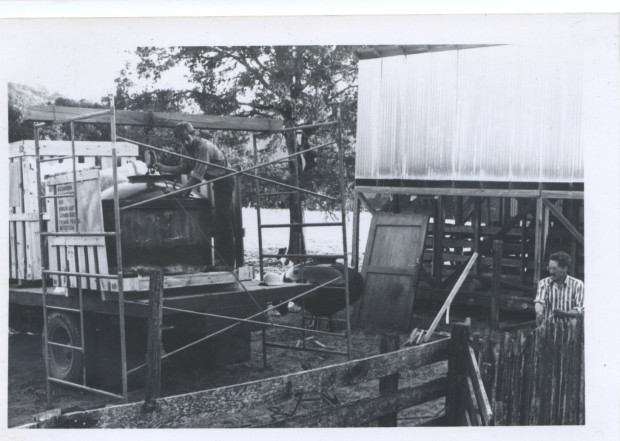

I had a 16-foot flat bed truck. We figured we could put the container on it, and drove it to the Port of Oakland. WRONG. When the crane tried to load it, it almost blew the tires. The importer took the container to his warehouse and put the crates on this flatbed. Here I am on the way out of Oakland.

When we got to the ranch, we didn’t want to rent a forklift to unload it.

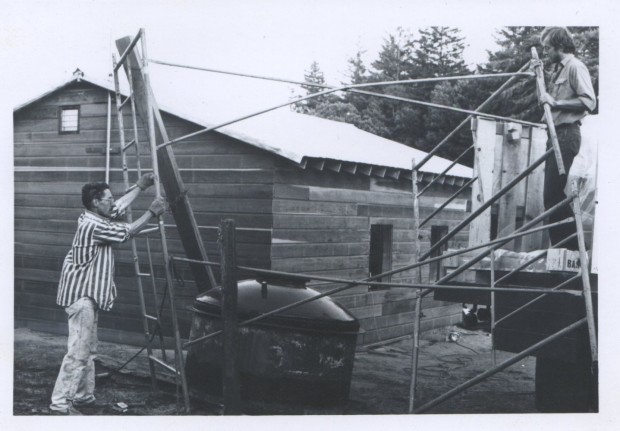

So we took the braces off one side of the scaffold, put a beam at the top, attached a block & tackle, backed the truck underneath the beam, and hooked it to the still’s main pot. You can see the preheater on the ground behind the scaffold. Then we drove out from underneath it.

The scaffold slowly and gracefully warped, depositing the pot on the ground like a baby’s kiss. It was a magic moment.

Here’s the pot on the ground. You can see where the scaffold frame bent.