Video Category: Notes from Ansley

Individual Products – Only Once No. 25

Individual Products: comments Special Heirloom Apple Brandy

Individual Products: Comments on Russell Henry Dark Gin

Notes on OId and Rare: 19 Year Evolution of Granache Brandy

Notes from Ansley: Baudoinia Compniacensis

Notes from Ansley: If You Want to Know Who We Are, Read This.

.

If you want to know who we are, right now, look at this. I’ve given a lot of tours to journalists: Kelli White’s sense of the right questions to ask was unique. Her article, posted in Antonio Galloni’s Vinous, is spot on. Nice to have it in such a well-regarded venue.

http://www.vinous.com/articles/germain-robin-french-original-american-twist-jun-2015

It’s what we can’t say ourselves straight out. Hubert and I took the finest of artisan cognac methods and improved on them: better grapes, better control of crush and fermentation. Too bad she came before we bottled for the Barrel 154 Chenin, which is the finest single spirit I have ever encountered. Her reviews are the deepest reviews we’ve ever had. She nails our brandies’ DNA.

“Decoding Germain-Robin: the markings on this barrel ‘FC(98) K(ML)’ indicate that the contents are 1998 French Colombard from the Kiefer Vineyard that went through malolactic fermentation.” –Kelly White

Notes from Ansley: Crispin’s take on his new 4 YR Wheat Whiskey

Crispin Cain of Tamar Distillery:

I started making experimental batches of whiskey in 1992, a small experiment. In 2008 a dear friend asked if I would explain distillation. He makes lots of homemade beer, so I asked, “what are you making beer from today?” “A malt extract of Bavarian wheat” was the answer, so that weekend we did the mash and, a few weeks later, distilled it in a tiny still. The spirit that emerged was remarkable and fine. I brought it to Ansley Coale and told him I planned to make whiskey!

This is a blend of 4 and 5 year old wheat whiskies, made in 2010 and 2011, the first that my son Devin and I made for the Low Gap label. As our first serious production, it took much blood, sweat, tears, but it also won Artisan Whiskey of the Year from Malt Advocate when we bottled some of it as clear whiskey. This release was aged in new and used bourbon barrels, used Cognac barrels, and used port barrels. The flavor profile is dense and very complex and (at 45.5% ABV) lends itself well to cocktails.

This whiskey is my favorite in a whiskey and soda, and also on the rocks. For maximum enjoyment, I recommend sipping slowly.

Notes from Ansley: Early Germain-Robin Part 3 Installing the Still

*

We worked with local masons Fred Rouse and Dave Butler. They didn’t believe us when we told them that this was the only such still in the USA.

We had a scale drawing made by Prulho, in centimeters. There was a lot of jawboning.

Here it is in place before they put the bricks around the pot. We insulated the pot with earth, sand, and diatomaceous earth, the way they used to. This means there is retained heat, which is beneficial around the pot. The same heat dissipates with modern cognac-still insulation.

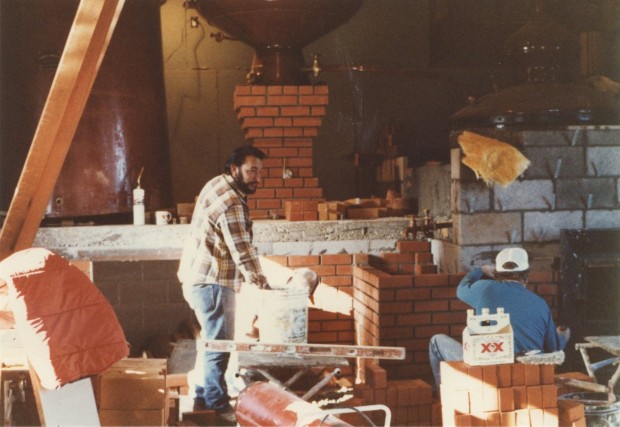

Dave and Fred laying the brick facing. Behind Dave is the brick pillar they built to hold the preheater. Elegant work.

Fred Rouse’s crew. They enjoyed the job.

Turkish workman Ansley checking it out. Note the rebar for finishing the chimney behind the pot and the leftover firebrick under the condenser platform.

Our lovely old, antique still. It makes very good brandy. We moved the operation in 1998, but we still use it once in a while.

Notes from Ansley: Early Germain-Robin Part 2

The Still Arrives

Hubert found a beautiful still, wood-fired when assembled in the 1930s, in an abandoned distillery near Cognac. He had it refitted at Prulho, who added two coils to the condenser and shipped it to California.

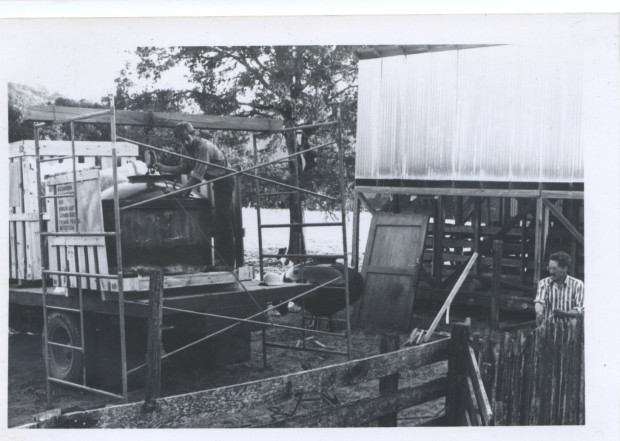

I had a 16-foot flat bed truck. We figured we could put the container on it, and drove it to the Port of Oakland. WRONG. When the crane tried to load it, it almost blew the tires. The importer took the container to his warehouse and put the crates on this flatbed. Here I am on the way out of Oakland.

When we got to the ranch, we didn’t want to rent a forklift to unload it.

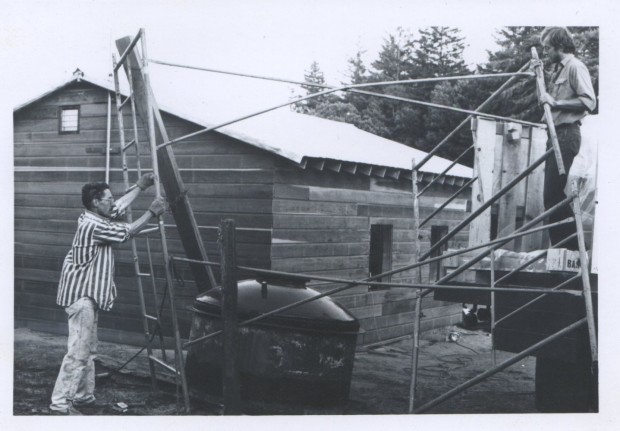

So we took the braces off one side of the scaffold, put a beam at the top, attached a block & tackle, backed the truck underneath the beam, and hooked it to the still’s main pot. You can see the preheater on the ground behind the scaffold. Then we drove out from underneath it.

The scaffold slowly and gracefully warped, depositing the pot on the ground like a baby’s kiss. It was a magic moment.

Here’s the pot on the ground. You can see where the scaffold frame bent.